Anaerobic digestion at wastewater treatment plants produces digester gas. This methane-rich byproduct can be an energy source, and a need for accurate biogas/digester gas measurement exists within the wastewater treatment facility.

Wastewater Digester

Wastewater digester gas is a methane-rich byproduct that can be an energy source. In large wastewater treatment plants, anaerobic digestion breaks down organic waste. The process produces digester gas from decomposing sewage sludge from primary or secondary clarifiers. A biogas flow meter can monitor biogas applications.

Wastewater Digester Gas Composition

Digester gas is biogas. Its composition varies, though the primary constituents are methane (CH4) and carbon dioxide (CO2). Trace amounts of nitrogen gas (N2), oxygen gas (O2), and hydrogen sulfide (H2S) may also be present. While the gas compensation can fluctuate depending on temperatures and the process, methane-rich gas (~60-70% CH4) becomes an attractive energy source. The biogas can burn in engines to create electricity or heat the digester tank to speed decomposition. Additionally, the biogas, at times, can be supplemented with natural gas to heat the facility.

Remember that digester gas is dirty and wet and often condenses, causing a build-up in the pipe and probes inside the piping.

Digester Gas Flow Meters for Wastewater Treatment Plant

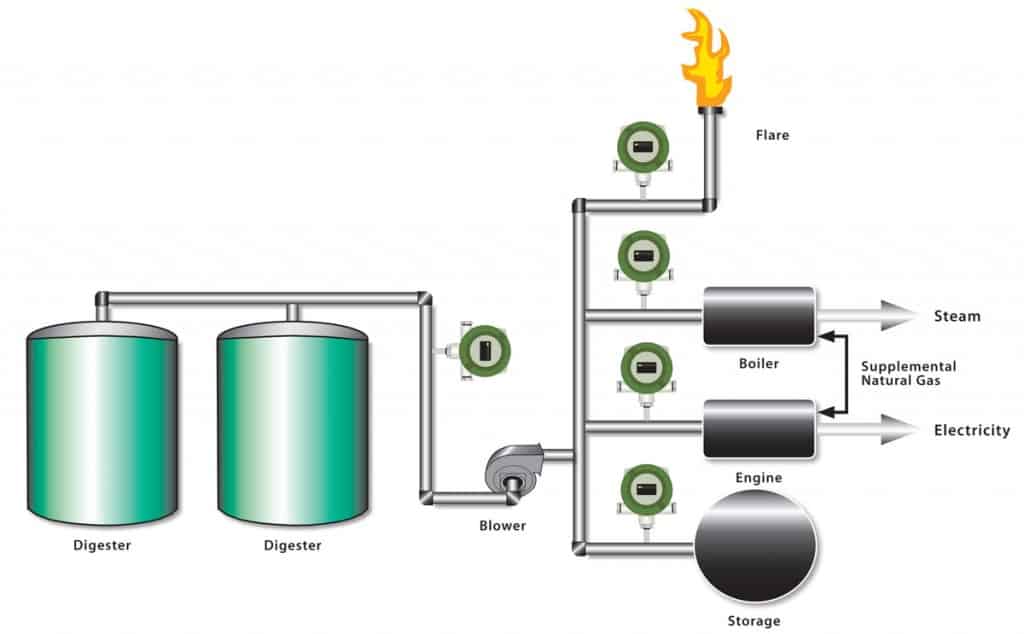

There are many opportunities to use thermal mass flow meters to measure digester gas flow or flare gas flow within a modern wastewater treatment process.

- Monitor the digester process performance

- Process control for cogeneration systems that use biogas gas as an energy source

- Flaring to convert methane (GHG) to less harmful CO2

- Collect data for GHG reduction and carbon credit programs

- Comply with environmental regulations to report greenhouse gas emissions

Considerations for Thermal Mass Flow Meter Selection

- Easy in-situ calibration verification method to verify the accuracy and operation of the sensor and transmitter

- Mass flow measurement without the need for temperature and pressure correction

- Gas from the digester is often low pressure and low flow rates, so the meter requires excellent low flow sensitivity and negligible pressure drop.

- Approved for use in Class I Div. 1 and Class 1 Div.2 hazardous area

- No moving parts reduce maintenance; advantageous over commonly used positive displacement flow meters or turbine meters

- Calibrated for the biogas composition

- A probe retraction device for easy removal for cleaning

- Wide turndown for precision measurement at low or high flow

- Temperature compensation for accuracy and repeatability with changing process and ambient temperatures

- Due to condensed moisture in the gas, the flow meter should be installed downstream of the moisture knockout pots

The Sage thermal mass flow meters meet and exceed the selection considerations for measuring biogas gas flow in wastewater treatment applications. Sage Metering is the only manufacturer offering an easy, in-the-pipe method to verify that the meter is accurate and that the sensor and transmitter are clean and operational.

Recommended Models for WWTP Digester Gas Applications:

Related Applications

Anaerobic digesters are commonly used in various industrial applications to produce biogas, including:

- Farmers use digesters for manure management and to create an energy source.

- Brewers use digesters in wastewater treatment for pollution prevention and create biogas for use in their boilers reducing natural gas consumption.

- Distillers use digesters to convert waste to energy and control pollution.

Download this Application Brief