The following is a technical note on using nitrogen gas flow meters in nitrogen blanketing. Sage Metering manufactures thermal mass flow meters and does not produce entire blanketing systems.

Many industries store liquids, gases, and even slurries in storage tanks or vessels. When the storage material comes in contact with oxygen, the substance oxidizes and degrades or potentially creates a hazardous situation.

Nitrogen Blanketing

Tank blanketing, N2 nitrogen blanketing, or tank padding introduces an inert gas, such as nitrogen (the most cost-effective), to a storage tank to counter the effects of oxygen on the storage material, which is usually a liquid. When purging a container with inert or inactive gas, the storage vessel material does not contact the oxygen. For this reason, the life of the product is prolonged and mitigates potentially explosive conditions.

Refineries, pharmaceutical companies, and the petrochemical industry use tank blanketing to prevent contact with oxygen and as a way to avoid potentially hazardous conditions. The blanketing process controls the atmosphere above a combustible or flammable liquid, reducing the ignition potential. Manufacturers use the method to store adhesives, chemicals, fuels, pharmaceuticals, photographic chemicals, inks, and soaps.

Industries that use Blanketing

-

- Food and beverage industry

- Petroleum industry

- Pharmaceutical industry

- Petrochemical industry

Food and Beverage

Food manufacturers use tank blanketing for storing cooking oils, fats, foods, and purified water to reduce oxidation, increase product shelf life, or prepare the product for transportation or final packaging. The FDA regulates gas-blanketing systems in the food industry. The manufacturer must follow strict maintenance programs to comply with all product-contact regulations regarding filter specifications, purity, and toxicity. When using inert gases, such as nitrogen, the user must follow strict protocols to ensure their workers are not exposed to harmful or lethal doses of any non-breathable substance. Additionally, in the United States, OSHA regulates any commercial use of tank blanketing.

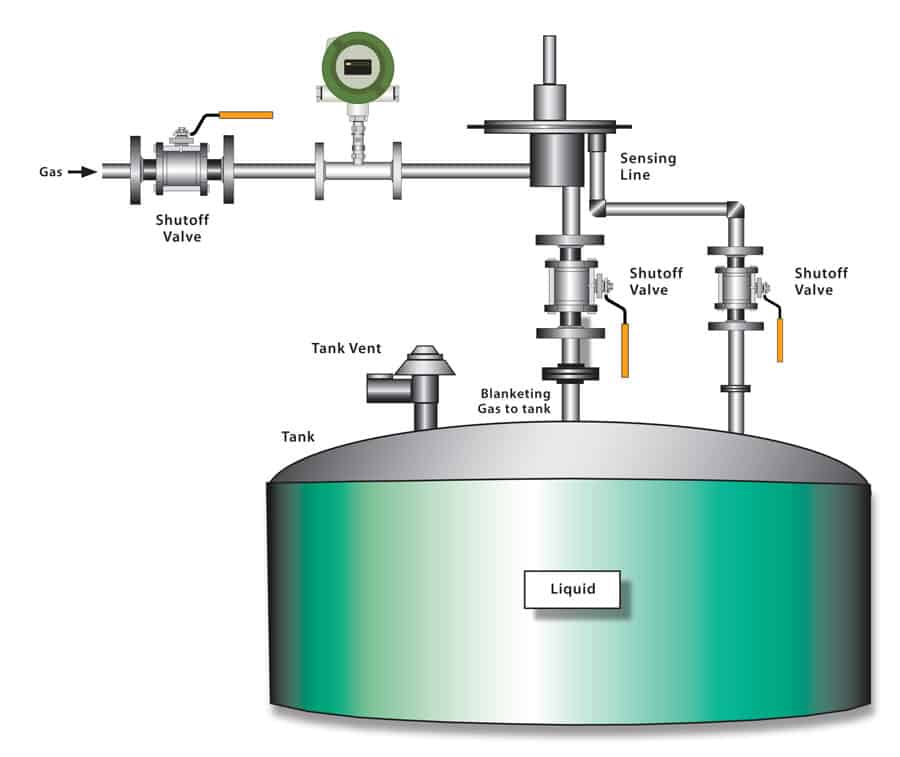

Tank Blanketing Systems

Tank blanketing systems are installed on fixed roof tanks. The system includes a valve that controls the nitrogen coming into the tank. The valve is continuously adjusted to maintain a slightly constant positive pressure in the tank’s vapor space. Usually, the valve is closed under static conditions, shutting off the flow. If there is leakage in the vessel, the pressure will drop, and to compensate, a low flow of nitrogen into the container will occur. Similarly, if the temperature drops, there is a decrease in pressure in the vapor space, and nitrogen will flow into the tank.

When emptying the tank, significant flow rates of nitrogen can result. In this case, it is essential to maintain positive pressure in the tank. If the tank pump-out rate is higher than the speed of nitrogen flow replacement, negative pressure can cause the tank to suck in and collapse.

Nitrogen Gas Flow Meter for Tank Blanketing

Facilities management is often interested in measuring the flow of inert gas (nitrogen) to monitor consumption. Thermal mass flow meters can measure and totalize the amount of inert gas. They also can alert the operator if the gas is leaking to prevent losses. Some systems use the expensive Coriolis meter, in which case the thermal mass flow meter offers significant savings.

The Sage thermal mass flow meter is available with remote electronics permitting the display to be at ground level rather than near the top of the tank, where the flow meter is likely installed.

The Sage meter measures the flow rate and provides a 4-20 mA signal. The meter’s display also shows totalized flow with a pulse output that an external totalizer can receive.

Considerations for Flow Meter Selection

- Mass flow measurement without the need for temperature and pressure correction

- Approved for use in Class I Div. 1 and Class I Div. 2 hazardous area

- No moving parts reduce maintenance; advantageous over positive displacement flow meters or turbine meters

- Calibrated for nitrogen gas composition

- Wide turndown for precision measurement at low or high flow

- Temperature compensation for accuracy and repeatability with changing process and ambient temperatures

- Easy in-situ calibration verification method to verify the accuracy, and operation of the sensor and transmitter

The Sage thermal mass flow meters meet and exceed the selection considerations for measuring nitrogen gas flow in tank blanketing applications. Sage Metering is the only manufacturer offering an easy, in-the-pipe method to verify that the meter is accurate and that both the sensor and transmitter are clean and operational.

Recommended Sage Models for Nitrogen Blanketing

The Sage Prime and Paramount are premium thermal mass flow meters that measure gas flow in industrial, commercial, and environmental applications. There are many similarities between the two meters. This article helps the reader understand the differences between the two to decide which meter to purchase.

Sage Prime – The flow meter’s sensor type will depend on the pipe size going to the tank blanketing valve (typically ½” or 1”). A Sage Prime with an in-line flow body would be used on either a ½” or 1” line, while the Prime with insertion probe is for pipes 1” and larger.

Sage Paramount – The Paramount uses updated microprocessor technology, providing a faster response to temperature fluctuations than the Prime. The Paramount has options available to it that the Prime does not have, such as Class I Div 1, HART Communication Protocol, or Bluetooth connectivity.