Sage Metering has one of the finest thermal mass flowmeter calibration facilities in the United States. All Sage calibration standards are NIST-traceable (National Institute of Standards and Technology). Below, we share information on our NIST-traceable equipment and protocols.

If your Sage meter fails its in-situ calibration verification and requires recalibration, you can submit an inquiry here.

NIST-Traceable Assets

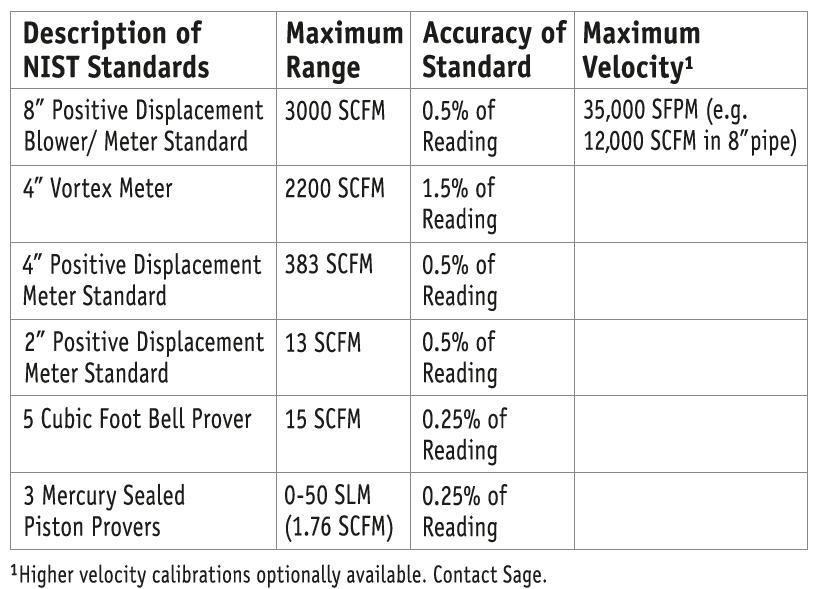

Our NIST-traceable equipment includes five standards with an accuracy of 0.50% or better (refer to table below).

-

- A 4″ vortex flow meter is used for diagnostic purposes.

- The primary standard equipment includes 2″ and 4″ positive displacement meters (Roots meters).

- For very high flow rate (high velocity) applications, we use an 8″ positive displacement Roots blower/flow meter. We can take data points up to 30,000 SFPM (~150 NMPS) and extrapolate to at least 20% above that to maintain published accuracy of 0.5% of full scale (FS) and +/- 1.0% of reading over a 100 to 1 turndown.

- We can use a bell prover or, if necessary, piston provers for extremely low flow rates.

Calibration Procedures

We temperature-calibrate every meter.

As for calibration procedures, we temperature-calibrate every flow meter in our proprietary facility, eliminating errors from process temperature changes. The data generated from this multi-temperature procedure is then loaded into the flow meter’s Modbus registers to eliminate any flow errors associated with temperature.

Flow rate dictates sensitivity.

Our facility also involves a process that sets the sensitivity for our customers’ applications. Low flow rate applications have high sensitivity (more heat applied to the flow sensor). High flow rate applications have much lower sensitivity (less heat applied to the flow sensor) to deal with the very high heat transfer of flare gas, compressed air, and other gases.

Pictured above is the Sage NIST calibration facility. Sage Metering established the 8″ Roots blower/meter in 2017. Note that the 8″ pipes go through valves to connect the 4″ flow section where the client’s flow meters are inserted for calibration.

We have smaller test sections to calibrate lower flow rates or smaller in-line flow meters.

Sage Metering is a closed-loop calibration facility.

Sage uses the actual process gas or gas mix specified by the customer. Unlike some manufacturers that only calibrate with air, we take the flow data with the actual gas or gas mix. [Note that the gas tanks in the image are the client’s actual process gas or gas mix for their application.]

Multiple data points and sampling achieve calibration.

In the Sage calibration protocols, we typically take at least 15 data points with 11 samples for each data point (making at least 165 points). The multiple samples per data point ensure that each flow point has settled, and thus, we get perfect calibration results. Finally, we use a curve plotting program to linearize the data on the curve and then enter six unique coefficients into the Modbus flow meter registers.

Sage is the pioneer of the In-Situ Calibration Verification.

In addition to our NIST-traceable calibration facility, Sage is the pioneer of the In-Situ Calibration Verification procedure, where the meter user can verify at any time that the flow meter retains its original NIST calibration with a simple 5-minute verification.

Download a PDF of Sage NIST-Traceable Calibration Procedure.

Download the Sage NIST-Traceable Calibration Flyer.