Flow profile impacts accurate flow measurement. Flow conditioners, or flow conditioning, improve a flow meter’s accuracy by delivering a uniform flow profile at the sensor location.

What is Flow Profile?

The accuracy of a flow meter is dependent on the flow profile of the substance in the pipe. The key factors affecting flow profile are the piping and straight run upstream of the sensor, while there is some minor impact from the downstream straight run. For this reason, the flow profile is a significant factor we need to understand to choose the right location for any thermal flow meter application.

The desired flow profile can usually be achieved with a distance of 15 to 25 pipe diameters of straight run upstream of the meter, following a single elbow. Greater distances are required for other pipe geometries. However, we cannot always provide sufficient straight-run to secure a “fully developed flow profile.”

What is Flow Conditioning?

Anytime there is a change in the size, the direction of a pipe in which gas flows, or a disturbance, the flow profile has been impacted, and accurate flow measurement is hindered. Whenever there is a limited straight run or a developed profile cannot be achieved, flow conditioning becomes necessary to create a known and repeatable velocity profile and to enhance the flow meter’s accuracy. What is a flow conditioner and conditioning? Flow conditioners, or flow conditioning, improve a flow meter’s accuracy by delivering a uniform flow profile at the sensor location.

In-Line Flow Body Style Meter

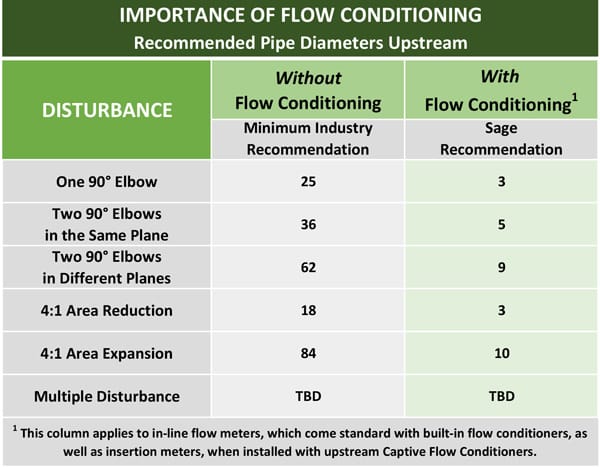

The flow conditioning is built into the Sage Metering inline flow body meter. The recommended upstream distances ahead of the flow body can be significantly reduced in these cases due to the built-in flow conditioning.

Insertion Style Meter

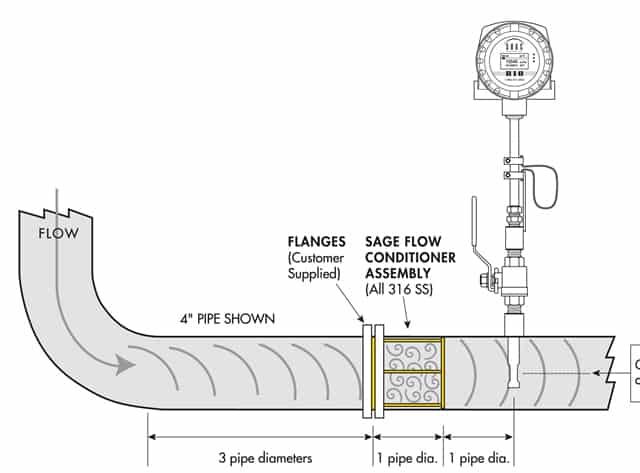

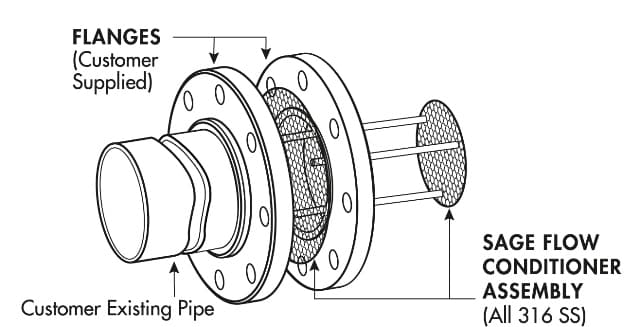

It is recommended that insertion style meters use a Captive Flow Conditioner assembly, consisting of two flow conditioner plates positioned between two flanges. (Pictured)

The chart on the right reveals the amount of straight run required for different pipe configurations for installations with and without flow conditioning ahead of the flow meter location.

Sage flow conditioners are sold along with insertion-style Sage meters. Because the flow profile following the flow conditioner is different from the normal fully developed turbulent flow profile that occurs with sufficient run, it is necessary to calibrate an insertion flow meter with the flow conditioner. Without sufficient straight run, the results’ repeatability is only assured when calibrating the meter with the conditioner and properly installing the units.

Perhaps, you are interested in Gary Russell’s Flow Profile and Flow Conditioning Article.