Flow profile significantly impacts accurate flow measurement. Flow conditioners improve a flow meter’s accuracy by creating a uniform flow profile at the sensor location, ensuring reliable results even in challenging pipe configurations.

What is a Flow Profile?

The accuracy of any flow meter depends on the flow profile of gas moving through the pipe. Key factors affecting this profile include piping configuration and the straight run upstream of the sensor, with some minor impact from downstream conditions. Understanding the flow profile is crucial when selecting the optimal location for a thermal flow meter installation.

A “fully developed flow profile” typically requires 15 to 25 pipe diameters of straight run upstream of the meter following a single elbow. More complex pipe geometries demand even greater distances. However, space constraints often make achieving these ideal conditions impossible.

What is Flow Conditioning?

When gas flow encounters changes in pipe size, direction, or other disturbances, the flow profile becomes disrupted, compromising measurement accuracy. Flow conditioning becomes essential when a limited straight run prevents achieving a developed profile naturally.

Flow conditioners create a known, repeatable velocity profile that enhances flow meter accuracy by delivering uniform flow patterns at the sensor location. This significantly reduces the straight-run requirements while maintaining measurement precision.

Flow Conditioning Solutions

Inline Flow Body Style Meters

Sage Metering inline flow body meters feature built-in flow conditioning. This integrated design significantly reduces upstream straight run distance while maintaining measurement accuracy.

Insertion Style Meters

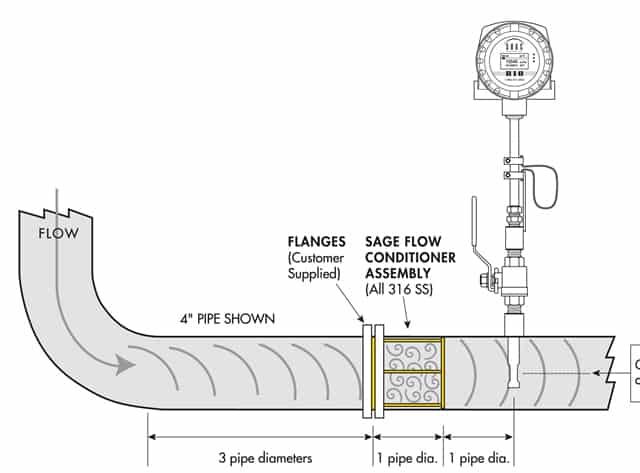

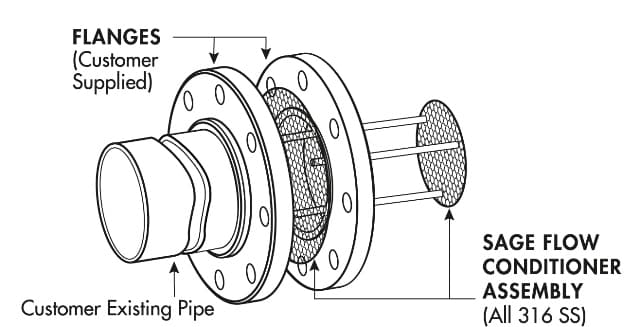

Sage recommends using a Captive Flow Conditioner assembly for insertion-style meters. This assembly consists of two flow conditioner plates positioned between two flanges, as shown in the image above. It creates a uniform flow profile even with a minimal straight run.

The Impact of Flow Conditioning

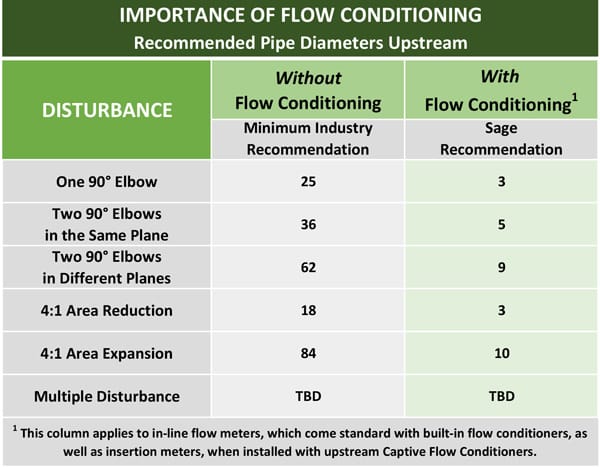

The chart below demonstrates how flow conditioning dramatically reduces straight-run requirements across different pipe configurations:

The chart on the right reveals the amount of straight run required for different pipe configurations for installations with and without flow conditioning ahead of the flow meter location.

Important Considerations

Since the flow profile after conditioning differs from a naturally developed turbulent flow profile, calibration must account for this difference.

Sage calibrates its insertion flow meters with flow conditioners for optimal performance to ensure accurate measurements. Without sufficient straight run, repeatability is only guaranteed when the meter is calibrated with the conditioner, and both components are properly installed.

For more detailed information, see Gary Russell’s Profile and Flow Conditioning Article.