Wastewater Treatment Plants and Aeration Airflow

What is Aeration Flow?

At wastewater treatment facilities, aeration flow is used to introduce air into the wastewater to create an environment that promotes the growth of microorganisms to decompose organic waste. The oxygen feeds or nourishes microorganisms within the basin, so the bacteria thrive and consume suspended particulates.

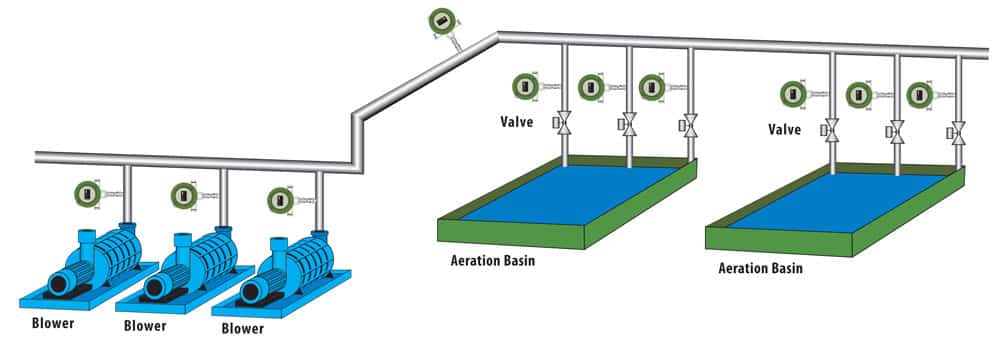

This may be achieved either through a mechanical agitation system or a subsurface air system. A mechanical system uses blades, propellers or brushes to agitate the wastewater to introduce air from the atmosphere. In a subsurface system, the air is introduced by blowers and diffusers submerged in the wastewater. Air blowers may feed the main header which serves multiple aeration basins. From the main header, the air flows to each aeration basin or each zone in an aeration basin. Depending on the design, flow meters may be used to measure the flow to each aeration basin or individual zones in each basin. The total amount of air flowing to the aeration basins is controlled by the dissolved oxygen (DO) meter in the basin.

In older systems, there was little control over airflow, as it was assumed that the more airflow, the better the decomposition. This viewpoint, however, has changed given the high cost of energy. Thermal mass flow meters may be installed in the main header to measure the total airflow from the blower/compressor. In this case, there is no control of the airflow to each basin; the meter is merely monitoring air flow to check the performance of the blower. Optionally, a flow meter may be installed on each branch line leading to an individual basin where the flow meter is used for balancing the air flow between basins or, in some cases, controlling the flow to each aeration basin.

Aeration Control

In the subsurface system, compressed air is one of the highest expenses, accounting for 40-60% of the facility’s operating cost. Aeration control provides the optimum amount of airflow to meet the oxygen demand of each zone while keeping the system pressure as low as possible. This helps prevent wasting costly air while achieving efficient decomposition. While control of the airflow to the aeration basin is based on the DO content, what is important is to ensure a proper balance of air flow to each zone.

Older systems operate at fixed speeds. They use multiple blowers feeding air into the same main-header. The control system may turn blowers on or off depending on oxygen needs. It may also adjust the flow to each zone in the aeration basin with the control valve. Newer systems have variable-speed drives on the blower which will reduce air flow in times of low demand, and control valves balance the flow in the aeration basin.

A successful aeration control system is dependent upon the efficient operation of its system components. The components for each region may include an airflow valve, air flow meter, and DO (dissolved oxygen) meter. The valve, commonly a butterfly valve is usually installed downstream of the flow meter. Much of aeration control is predictive, as there is a nonlinear relationship between the airflow and dissolved oxygen content which creates a lag time to reach equilibrium.

Thermal Mass Flow Meters in Aeration Flow

Three technologies are used to measure aeration airflow: orifice plates, vortex shedding, and thermal mass flow meters. The thermal mass flow meter is the preferred method to measure airflow at wastewater treatment facilities. They require lower maintenance, are easier to install and save on energy costs. As older aeration systems with vortex and orifice meters are being replaced or upgraded, thermal mass flow meters are being integrated into the systems. The upgrades improve the aeration process, and this saves money and cuts maintenance costs.

The thermal mass flow meter’s accuracy and repeatability serve the aeration process well. The thermal meter can measure over a wide flow range (high rangeability) making it accurate in changing operating conditions. Thermal mass flow meters also measure mass flow, so unlike other metering options, pressure and temperature devices are not needed. The insertion-style flow meter is easy to install through a single tap point, and the small sensor creates a minimal pressure drop, allowing the blowers to run at lower power levels and reduce energy consumption.

If an aeration system lacks sufficient straight run, flow conditioners may eliminate flow profile distortions. Because there are no moving parts, there is nothing to clean, repair, wear out, or clog. The thermal mass flow meter provides excellent reliability and long-term maintenance-free operation. Also, the Sage Prime can have its calibration verified while in the field without stopping the process or removing the meter from the pipe.

Considerations for Flow Meter Selection

The benefit of thermal mass flow meters in this application is:

- Mass flow measurement without the need for temperature and pressure devices

- Easy to install an insertion probe directly in the pipe

- High rangeability

- Creates minimal pressure drop

- Excellent reliability provides long-term maintenance-free operation

The Sage thermal mass flow meters meet and exceed the selection considerations for measuring aeration airflow at wastewater treatment plants. Additionally, Sage Metering is the only manufacturer offering an easy, in-the-pipe method to verify that the meter is accurate and that both the sensor and transmitter are clean and operational.

Recommended Models for Aeration Airflow:

Sage Prime–The Remote style meter permits the operator to view the air flow from a convenient location.

The Sage Prime is ideal to monitor the main blower air header as well as the branches leading to the aeration basin. In larger systems, even the drop lines to individual zones can be monitored. Additionally, effective control of the blowers can reduce energy costs by as much as 25% (when comparing adjusting the blowers manually, or leaving the blowers on permanently).