The thermal mass flow meter can be used as an air mass flowmeter to measure the combustion air to boiler fuel. Additionally, it can serve as a compressed air flow meter to monitor compressed air in various processes.

Industrial Air Mass Flow Meter

There is a need for accurate air mass flow measurement. This Sage technical note explores using thermal mass flow meters to measure combustion air to boiler fuel (to assure the proper ratio of fuel to air). This article also explores monitoring compressed air in various industries and processes. Both of these applications improve the efficiency of the process and reduce costs.

In the market for a mass flowmeter?

All About Air

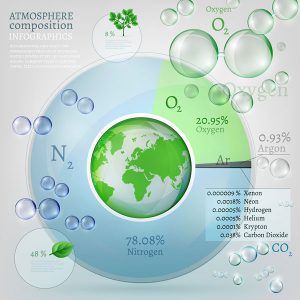

Air is the most common gas on Earth and supports life. Dry air consists of nitrogen (78%), oxygen (21%), argon (>1%), and trace amounts of carbon dioxide, methane, hydrogen, helium, and neon. Additional gases that are considered pollutants may also be present in the parts per million range, such as sulfur dioxide, nitric oxide, and carbon monoxide.

The water content of air will vary depending on the region ranging from 1% to 4% in hot and high humidity areas.

Using the ideal gas law, one may calculate air density at different pressures and temperatures. The dry air density at standard conditions for temperature and pressure (STP) (70° F and 14.7 psi) is 0.0749 lb./ft3. The density will vary based on the temperature and pressure. For example, at 90°F and an elevation of 5000 feet, with a pressure of 12.2 PSIG, air density is 0.060 lb./ft3. However, compressing the air to 100 PSIG at 70° increases the density to 0.58 lb./ft3.

While most mass flowmeters measure the flow rate at the actual conditions where the measurement is taking place, the general practice relates the flow rate to STP conditions, requiring knowing the air’s pressure and temperature at the measurement point. Flow measurements at STP conditions are mass flow since they refer to specific operating conditions.

Flow Rate or Total Flow?

There are two ways of measuring and reporting airflow. In one case, the flow reports as the total flow since the previous reading. In this case, the measurements can be in units of SCF (standard cubic feet), pounds, kilograms, or regular cubic meters. More often, the flow rate over a specific time is desired, such as SCFM (standard cubic feet per minute) or pounds per hour.

Combustion Air Flow

Combustion is the burning of air and fuel. The most efficient combustion occurs with an optimum amount of each. The air-fuel ratio is the mass ratio of air to fuel present. If there is too little air, incomplete combustion occurs, which results in lower combustion efficiency plus emitting unburnt fuel into the atmosphere. Alternatively, too much airflow means excess heated air releases into the atmosphere. Thus, there is a waste of energy. For more information on combustion efficiency, see the Sage white paper, “Combustion Efficiency and Thermal Mass Flow Meters.”

Compressed Air Flow Meters

Measuring the compressed air flow rate in industrial facilities can help determine when and where compressed air is used, identify wastage, and thus improve operational efficiency. If there are multiple air compressors, knowing the flow rate from each can help optimize compressed air distribution and help determine the compressors’ effectiveness. Optimization of the compressed air flow may defer acquiring a new compressor. Additionally, the air mass flow measurements can help size new compressors when appropriate to purchase. Air mass flow measurements may also determine if it is acceptable to shut down a compressor during periods of reduced airflow requirements. Due to the low-flow sensitivity of thermal flow meters, the devices can serve in leak detection if the compressed air demand is off. More information on using thermal mass flow meters to determine compressed air flow is in Sage Metering’s “ISO 50001 Energy Management” white paper.

How do you measure air flow?

Different types of instruments measure airflow. These include differential pressure flow meters (orifice, venturi, averaging Pitot tubes), vortex shedding, turbine, and positive displacement meters. These instruments measure the airflow at the actual conditions and require pressure and temperature measurements to obtain mass flow at STP conditions.

An advantage of the thermal mass airflow meter is that it does not need additional pressure and temperature measurement devices. The meter measures the mass flow of the air referenced to STP conditions. Thermal mass flow meters can also handle sizeable compressed air pipes even if heated. Additionally, the meters offer extremely high rangeability; the insertion probe is effortless to install in a pipe or duct. It can measure very-low flow rates. They do not create any pressure drop and are the most cost-efficient meter to obtain mass flow. See the Sage white paper, “Fundamentals of Thermal Mass Flow Measurement,” for more information on this meter type.

Compressed Air Snags and 7 Ways Thermal Mass Flow Meters Help

Considerations for Mass Flow Meter Selection

- Attain direct mass flow measurement (there is no need for temperature and pressure devices)

- User-friendly and easy to install an insertion probe directly in the pipe

- Probe retraction assembly permits removal or insertion of the probe in pressurized pipes

- The meter’s calibration can be easily and quickly verified while installed and in the field

- High rangeability

- Able to measure the highest possible flow rates

- Creates minimal pressure drop

- Excellent reliability provides long-term maintenance-free operation.

Related Air Flow Applications

- Building-exhaust air mass flow to ensure proper ventilation

- Cooling air mass flow to a heat-generating device to prevent damage

- Wastewater aeration air flow

How many types of flow meters are there?

What are two ways to measure flow?

There are two ways of measuring and reporting flow. In one case, flow is indicated by the total flow since the previous reading, and the measurement can be in units of SCF (standard cubic feet), pounds, kilograms, or regular cubic meters. More often, the flow rate over a specific time is desired, such as SCFM (standard cubic feet per minute) or pounds per hour.

Recommended Sage Models for Air Flow Applications

Leading energy management consultants often recommend using thermal mass flow meters.

View the Sage Metering YouTube channel for its videos.