A recent article by Bob Steinberg, Sage Metering President and CEO, reveals that accessing flow meter diagnostics helps users maintain their meter’s performance, reliability, and accuracy. He stresses the importance of diagnostics and how accessing them through configuration software, such as SageCom, saves the user time and money and verifies the meter’s accuracy.

What are the 4 ways to access diagnostics?

Each thermal mass flow meter manufacturer provides ways to access their meters’ diagnostics. There are four main ways, including a new direct communication method (exclusive to Sage at this point) to access the configuration software, which offers unique benefits to the meter’s users.

The four main ways to access flow meter diagnostics:

-

- Push Buttons

- Configuration Software

- SCADA System or PLC

- Direct Access Communication (NEW from Sage)

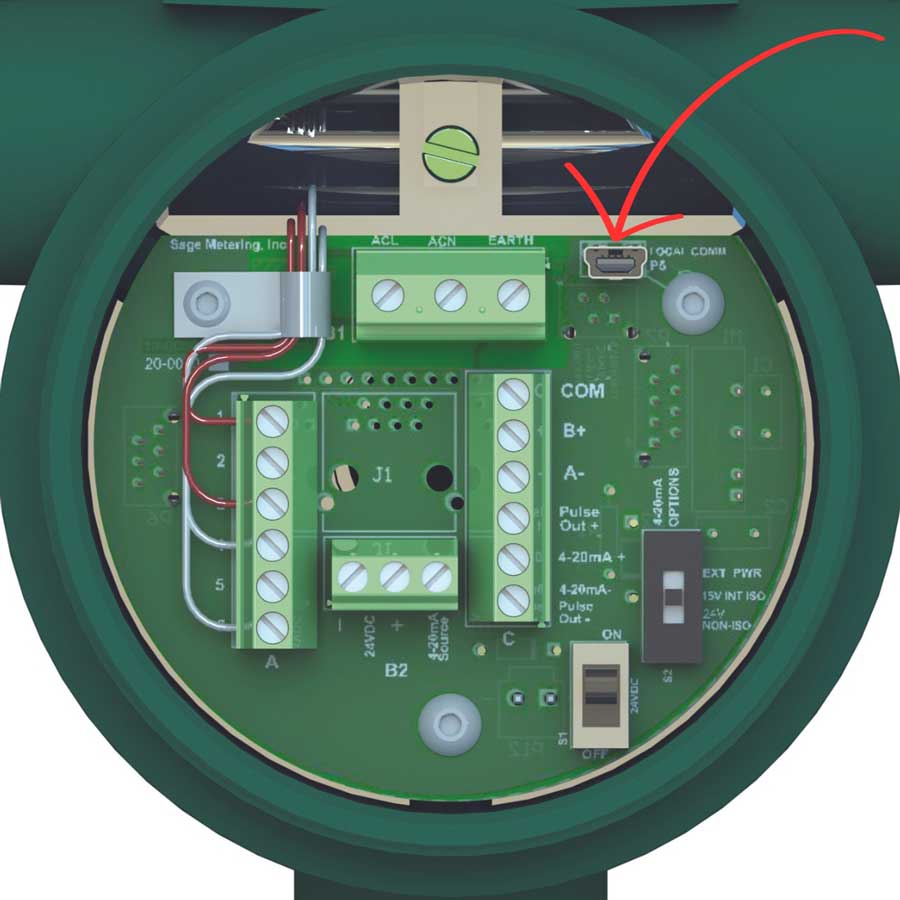

Convenient direct access permits communication between the meter and the configuration software on a PC.

Benefits of the Configuration Software

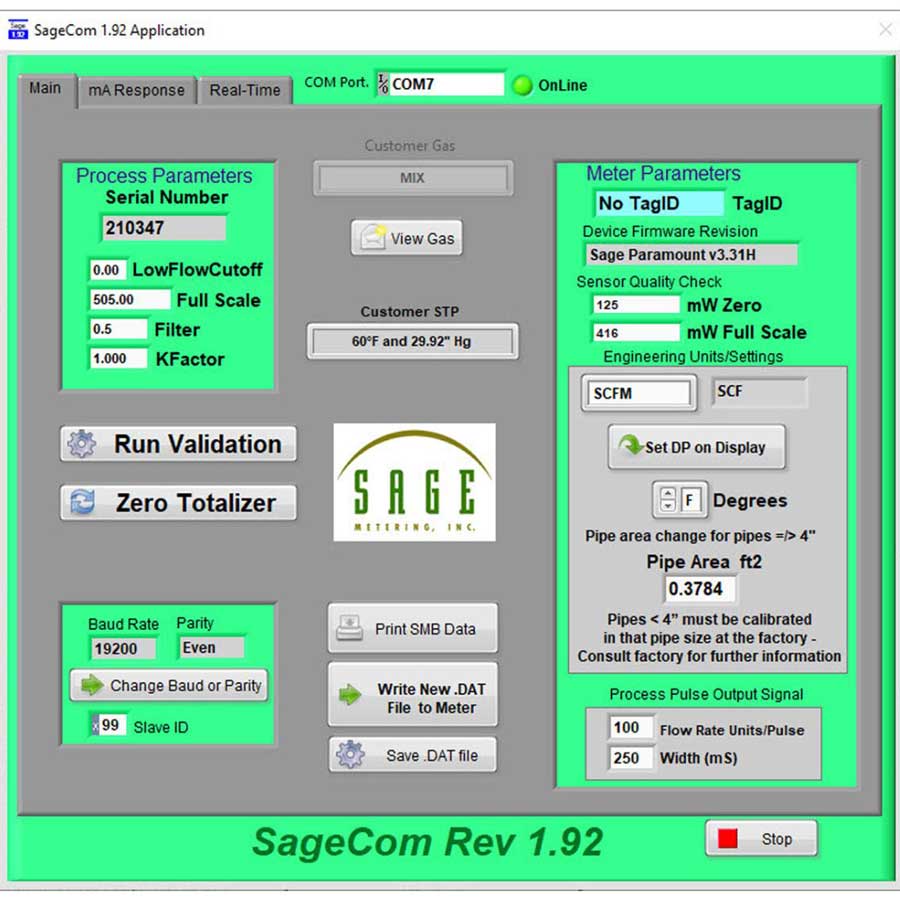

A flow meter is manufactured to specific parameters given by the user to the manufacturer when ordered. Sometimes, these parameters provided are incorrect. Other times the process conditions change. In any case, the user can easily adjust many parameters using configuration software, or the meter won’t be accurate.

Among the benefits of configuration software mentioned in the article is that some software (SageCom) verifies that the meter’s sensor is clean, accurate, and within calibration. In some cases (SageCom and Sage Paramount/Prime), this occurs while the meter remains in the field without removing it from the pipe. These self-check procedures save the cost of uninstalling and returning the meter to the factory and returning the meter to service.

The software menu above demonstrates some of the variables the user can adjust.

6 Common Reasons to Access SageCom Software

Mr. Steinberg’s article highlights the benefits of configuration software and provides six common reasons users access the configuration software:

-

- Underestimated full-scale flow rate

- Wrong Schedule pipe

- Gas mixture changed

- Setting a low flow cut off

- Miscellaneous adjustments

- Access diagnostics

Direct Access Communication

The article offers some distinct advantages of the direct access communication methods only offered through the Sage Paramount, which has a built-in communication port permitting direct communication between a meter and a laptop, and options for Bluetooth and Ethernet.

The article “Accessing diagnostics and the importance of configuration software for thermal mass flowmeters” is published on P.I. Process Instrumentation.