In Part VII of our natural gas flow meter types series, I discuss the orifice plate, a differential pressure meter commonly used to measure natural gas flow when high accuracy is not required.

Please note that Sage Metering does not manufacture orifice meters. We are a leading manufacturer of thermal mass flow meters and provide this information for our reader’s needs. If you would like to learn more about the thermal mass flow meter, take a look around our website and let us know how we can help you.

Differential Pressure Natural Gas Flow Meter

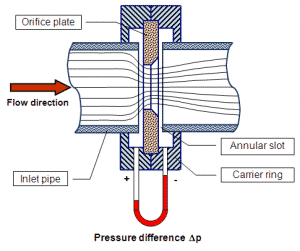

Differential pressure (DP) flowmeters determine flow by measuring pressure drop over an obstacle inserted in the flow pathway. These flow devices are orifice plates, averaging pitot tubes, venturi tubes, and flow nozzles.

Orifice Plates

The orifice plate (orifice meter) is a differential pressure meter frequently used in natural gas measurement. It measures volumetric flow, though it can also calculate mass flow depending on the device’s calculation. It uses the same principle as a Venturi-style meter (Bernoulli’s principle), suggesting a relationship between the velocity and pressure of the fluid. That relationship is – as the velocity increases, the pressure decreases. The orifice meter determines the flow through the difference in pressure between the upstream and the downstream side of a partly impeded pipe.

Advantages

- Orifice plates have a long history of documented use and have broad industry acceptance.

- They are inexpensive and straightforward.

- They have no moving parts and are mechanically stable.

- Dry calibration is acceptable.

- There are no limits on temperature, pressure, or size.

Limitations

On the downside:

- Orifice meters have low accuracy in low flow conditions.

- They have low turndown/rangeability and a high-pressure loss, which can impact operating costs.

- Orifice plates are flow-profile sensitive and require a long meter tube or flow conditioner.

- They are not self-cleaning and can be damaged or clogged by high flow rates.

- To calculate mass flow temperature and pressure correction is required.

Orifice Plate Manufacturers

There are many differential pressure orifice plate manufacturers, too many to list in this post.

If you are interested in learning more about other natural gas flow meter styles, read more.

Who are we?

We are Sage Metering. We manufacture thermal mass flow meters, which measure and monitor gas mass flow. If you are interested in a different meter style, may I suggest learning more about the advantages of thermal mass flow measurement? Otherwise, here are other links to articles sharing the benefits and limitations of each technology:

- Rotary meters

- Gas turbine meters

- Ultrasonic meters

- Coriolis flowmeter

- Diaphragm meters

- Thermal mass flow meter