The Sage Paramount thermal mass flow meter is now available with an optional Class I Division 1 approval (CID1 Groups B, C, D, T6) to provide the need for an explosion-proof flow meter in hazardous areas.

Hazardous Locations

Hazardous locations are places where fire or explosion hazards may exist because flammable gases may be present. Due to the inherent danger in these areas, there is a need for certified explosion-proof equipment in these locations. Such accreditations confirm that a product was tested and certified to conform to standards mandated through an independent agency.

Hazardous locations are places where fire or explosion hazards may exist because flammable gases may be present. Due to the inherent danger in these areas, there is a need for certified explosion-proof equipment in these locations. Such accreditations confirm that a product was tested and certified to conform to standards mandated through an independent agency.

Met Labs/Eurofins certified that the optional Sage Paramount meets the requirements for Class I Division 1 approval (CID1 Groups B, C, D, T6).

Group B – hydrogen, butadiene, ethylene oxide, propylene oxide, and acrolein

Group C – Ethylene, cyclopropane, and ethyl ether

Group D – Acetone, ammonia, benzene, butane, ethanol, gasoline, hexane, methane, methanol, naphtha, natural gas, propane, and toluene

Group T6 – Maximum permissible temperature of 85°C on any surface in contact with flammable gas or ignitable dust

Paramount Industrial Thermal Mass Flow Meter

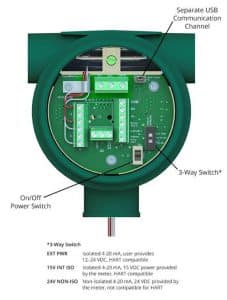

The Paramount™ mass flow meter for industrial applications is Sage’s latest model using advanced technology. The meter features the Sage Prime’s display, and circuitry, with a NEMA 4X enclosure, which safeguards the meter against harsh environmental elements providing extra corrosion protection. The rear compartment of the meter’s display is entirely separate from the electronics and has larger well-marked terminals that are easy-to-access. It features a mini-USB port to connect from the Paramount to a PC directly with a supplied cable. When using the SageCom software (free with the Paramount meter purchase), the user can quickly reconfigure the meter while in the field.

SageCom Validation and Configuration Software

Software Diagnostics

- Verify that the thermal mass flow meter is performing within original calibration and that the sensors are clean

- Confirm that the meter is measuring flow based on the initial factory calibration and that the linear output is correct

- Print a validation report

Software Reconfigurability

Software Reconfigurability

Check or change the configuration of the instrument (e.g., change full scale, pipe size, engineering units, decimal points)

Change Gas Mix in the Field

Enter an entirely new set of gas mix constituents versus the original calibrated mix, and the meter will automatically correct its readings to the updated mix

Log Real-Time Data

Export real-time data easily to Excel

Free SageCom Software with Paramount Order

Want More Information?

The meter is a 2019 and 2020 Flow Control Innovation Awards Nominee.

Tutorial for SageCom Validation and Configuration Software

If you have any questions or would like more information, message us here.

Images by Clker-Free-Vector-Images and Pete Linforth from Pixabay