Natural Gas Flow Meter Types

There are four natural gas meter types often used for flow measurement. They are mass flow meters, velocity flow meters, differential pressure, and PD meters.

What is a flow meter?

A flow meter is a precision instrument that measures a pipe’s gas flow rate (or liquid flow). While there are four main meter styles for flow measurement, here are three characteristics to determine flow:

- Positive displacement meters collect a fixed fluid volume, then release and refill the gas or liquid. Then, tally how many times the capacity fills to determine the flow.

- When measuring the rate of fluid over a known area, one can determine the flow.

- Other methods depend on the flowing stream’s forces as it overpowers a known constriction and indirectly calculates flow.

In the market for a mass flow meter?

Actual Flow vs Standard Flow

Since gas is compressible accurate gas flow measurement is difficult. As the temperature increases, the gas molecules move further apart. Conversely, as the pressure increases, the gas molecules move closer together.

Most gas flow meters (differential pressure, turbine, positive displacement, vortex shedding) measure the gas flow at the actual operating conditions. This flow rate is ACFM (actual cubic feet per minute). However, it is more important to adjust or correct the flow rate for a particular pressure and temperature. This adjusted flow rate is often called STP (standard pressure and temperature) and is usually in units of SCFM (standard cubic feet per minute).

For this reason, most gas flow meters require pressure and temperature correction to convert the flow rate from operating conditions (ACFM) to standard conditions (SCFM).

Flowmeter Styles

1. Direct Mass Flow

Mass flow meters determine mass flow passing through the meter. Two types deserve mention here:

Coriolis flowmeters provide a direct mass flow measurement based upon the fluid’s deflection force moving through a vibrating tube. These meters are highly accurate with high turndown capabilities and are independent of fluid properties. They are also costly to purchase and install and unsuitable for larger pipe sizes.

Thermal mass flow meters measure the mass flow based on heat transfer from a heated element. The gas molecules create the heat transfer; the greater the number of gas molecules in contact with the heated surface, the greater the heat transfer. This flow measurement method depends only on the number of gas molecules and is independent of the gas pressure and temperature; therefore, additional pressure and temperature equipment are unnecessary. They also provide excellent accuracy and repeatability and are easy to install.

2. Velocity

In a velocity meter type, the rate of the medium passing through the meter determines the measurement.

Turbine flow meters measure volumetric flow based on fluid flowing past a free-spinning rotor, each revolution corresponding to a specific volume of gas or liquid. The meters have high turndown and accuracy. Unfortunately, because of the meter’s moving parts, its use is limited to clean dry gases only in gas applications, and pressure and temperature compensation are required.

Ultrasonic flow meters measure the difference in pulses transit time that travels from a downstream transducer to the upstream sensor, compared to the upstream transducer back to the downstream transducer. This meter style is highly accurate but very expensive, and pressure and temperature measurements are required.

The vortex gas flow meter has a shedder bar (an obstruction) in the flow path, causing the fluid to flow around the shedder bar and creating vortices on the backside of the bar. The frequency of vortex generation is a function of the gas velocity. Fluid velocity is determined based on the principle known as the Kármán effect. The frequency of vortex shedding is independent of the fluid composition. The meter requires temperature and pressure compensation and needs a minimum flow rate to produce vortices.

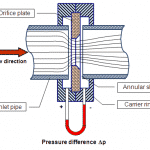

3. Differential Pressure Meters

Differential pressure flow meters calculate flow by measuring pressure drop over an obstruction inserted in the flow path. Common types of flow elements are orifice plates, flow nozzles, venturi tubes, and averaging pitot tubes.

The orifice plate is a differential pressure meter frequently used for natural gas measurement. It measures volumetric flow, not mass flow. This meter’s limitations include reduced low flow sensitivity, limited turndown, and a pressure drop, impacting operating costs. Additionally, it requires temperature and pressure correction to achieve mass flow since it’s a volumetric flow meter.

An averaging pitot tube is a differential-pressure flow measurement device commonly used for combustion air measurement. The device has limitations with measuring gas flow, especially low-flow sensitivity and turndown. The measure is contingent upon achieving velocity pressure, and if the current is too low, the user may not obtain adequate signals.

4. Positive Displacement Gas Flow Meter

Positive displacement meters require fluid to displace components mechanically and measure volumetric flow at the operating temperature and pressure. While they have sufficient accuracy, pressure and temperature compensation are needed to achieve mass flow, and since they have moving parts, the user must consider gas cleanliness. A PD meter may be called a PD flow meter or a volumetric flow meter. An example of a PD meter is the diaphragm meter.

Why is measuring mass flow important?

See our other videos on YouTube.

Downloads

eBook—An Industry Guide for the Use of Thermal Mass Flow Meters: Oil & Gas Production, Waste Management, Steel. Download the eBook for FREE.