We discuss the ultrasonic meter in this continuing series on natural gas flow meter types. This meter measures the natural gas volume and excels in custody transfer. While this flow meter measures liquids and gases, this post highlights information on natural gas.

Natural Gas Flow Measurement

Our blog typically discusses applications for thermal mass flowmeters because that is our business. Thermal mass flow meters serve various applications, and blogs, such as this one, allow readers to learn the pros and cons of other meter styles, in this case, the ultrasonic flow meter, which is an approved custody transfer meter for natural gas.

Transit-Time Ultrasonic Flow Meter

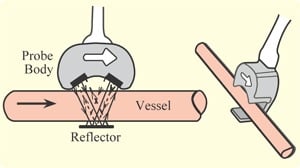

An ultrasonic flow meter calculates the fluid volumetric flow. There are two leading types, the transit time and the Doppler style meter. In the transit-time ultrasonic flow meter, the transducers are upstream and downstream, and each acts as a transmitter and receiver. Of course, one transducer emits the ultrasound signal with the flow, while the other emits it against the flow. The meter measures the difference in transit time between the two transducers, and the velocity difference is used to calculate flow.

Over the years, there have been technological advances that have helped improve the limitations of the meters. For example, electronic processing improvements have permitted the meter to measure some fluids that aren’t clean. Additionally, the introduction of a multi-path transit-time meter allows the meter to measure flow at more than one location, which increases the meter’s accuracy and permits measurement in demanding flows (swirls, irregularities, and cross-flow).

Advantages

The ultrasonic flow meter is highly accurate, usually within 1%, and is approved for use in custody transfer (fiscal metering). The meter has good repeatability, high turndown, and rangeability, and can measure at high and low pressures. The device tolerates high and low temperatures, and the user can fasten the clamp-on style outside the pipe without penetrating it. It is self-diagnosing, and the meter requires less frequent calibrations once calibrated. Since the meter has no moving parts, it has lower maintenance because it does not have to be lubricated or parts do not have to be replaced. Additionally, the meter has long-term reliability.

Ultrasonic meters can also measure flows in large pipe sizes, unlike other popular choices (like Coriolis meters). As a result, ultrasonic meters are used more in pipes 6″ and larger.

The ultrasonic meter works better than magnetic meters for oil and gas since gases and hydrocarbons are non-conductive.

Limitations

At the onset, ultrasonic meters are costly. Additionally, the ultrasonic flow meter is disturbed by noise and can be impacted by dirt and fluids. The pipe walls can interfere with signals for the clamp-on ultrasonic meters, and buildup on the pipe walls can affect the accuracy. Additionally, if one needs to determine mass flow with an ultrasonic meter, pressure and temperature measurement is required because ultrasonic meters calculate volumetric flow.

Ultrasonic Meter Manufacturers

Some ultrasonic flow meter manufacturers are Daniel (Emerson), Endress+Hauser, FMC Technologies, GE Measurement & Control Solutions, Greyline, Honeywell (RMG), Instrumart, Krohne, and Sierra.

Who is Sage Metering?

If you are interested in learning about other meter styles, may I suggest visiting our other reviews sharing the benefits and limitations of each technology:

Photo: Wikipedia public domain