Here I discuss another positive displacement meter in our continuing series on natural gas flow meters, the rotary meter. While this meter was initially introduced to measure liquids, much of this post is dedicated to measuring natural gas. The rotary style meter excels in measuring high-volume applications for utility billing and submetering.

Natural Gas Flow Measurement

Our posts frequently share applications for thermal mass flow meters because that is our business at Sage Metering. Our thermal mass meters excel in various applications, but other meters work well in other gas flow measurement areas. For this reason, this series introduces some other metering alternatives.

Have you considered a thermal mass flow meter?

Rotary Meters

The rotary meter is often called a rotary piston meter. The technology was initially introduced in 1846 by the Roots brothers in the water pump design. In 1920, the first gas rotary meter was released using the lobed impeller model from the Roots brothers’ design. Over the years, there have been many improvements in materials, modular design, manufacturing, and electronics.

PD Meters or Positive Displacement

The rotary meter is in a class of meters called positive displacement or PD meters. PD meters are recognized as having a history of success, a high degree of accuracy and remain the industry’s workhorses, even though other technologies have advanced. The PD meter requires fluid flow to physically or mechanically displace its components to measure the volume; therefore, it achieves volumetric flow.

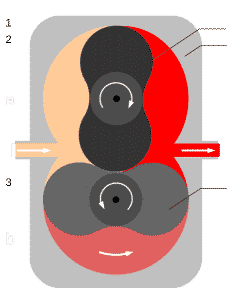

These precision-machined meters contain two figure-8 shaped lobes that spin in correct alignment. With each rotation, they displace a precise quantity of the substance measured. Another PD meter is the diaphragm meter, which also serves well in gas billing. Rotary meters, however, are capable of handling higher volumes and pressures than the diaphragm meter.

Advantages

The rotary meter is recognized for its accuracy and is used in utility billing and submetering. Over the years, as well-served diaphragm meters are taken out of service, notably the larger commercial and industrial-sized meters, many are replaced with a lighter and smaller rotary meter.

Limitations

The meter has moving parts, therefore limited to metering clean, dry gases. Since the meter measures volumetric flow, it also requires pressure and temperature compensation to obtain corrected gas flow.

Manufacturers

Manufacturers of rotary meters for natural gas include Honeywell Elster, GE Measurement & Control Solutions (Dresser Roots), Romet Limited, and others.

If you are interested in learning more about other styles of natural gas flow meters, read more.

Who are we?

We are Sage Metering. We manufacture thermal mass flow meters, which measure and monitor gas mass flow. If you are interested in a different meter style, may I suggest learning more about the advantages of thermal mass flow measurement? Otherwise, here are other links to articles sharing the benefits and limitations of each technology:

- Coriolis Flowmeter

- Diaphragm Meters

- Gas Turbine Meter

- Ultrasonic Flowmeters

- Orifice Plates

- Thermal Mass Flow Meters

Photo: Wikipedia (Rainer Bielefeld)