A thermal mass flow meter measures the mass flow rate and consumption of gases for commercial, industrial, and municipal functions.

Thermal mass flow meter: Direct gas mass flow measurement

Thermal mass flow meters are ideal for determining the mass flow of low gas flow applications. The meters directly measure gas mass flow and are frequently used in energy management systems, industrial process control, environmental applications, and building management systems. Since introducing these meters in the 1970s, they have undergone considerable development, from analog to digital, from low flow to higher flow, and from laboratory applications to industrial environments and hazardous areas.

There is a suitable thermal mass flow meter for almost every low-flow gas application. Other low-flow gas application measurement technologies include Coriolis flow and differential pressure measurements.

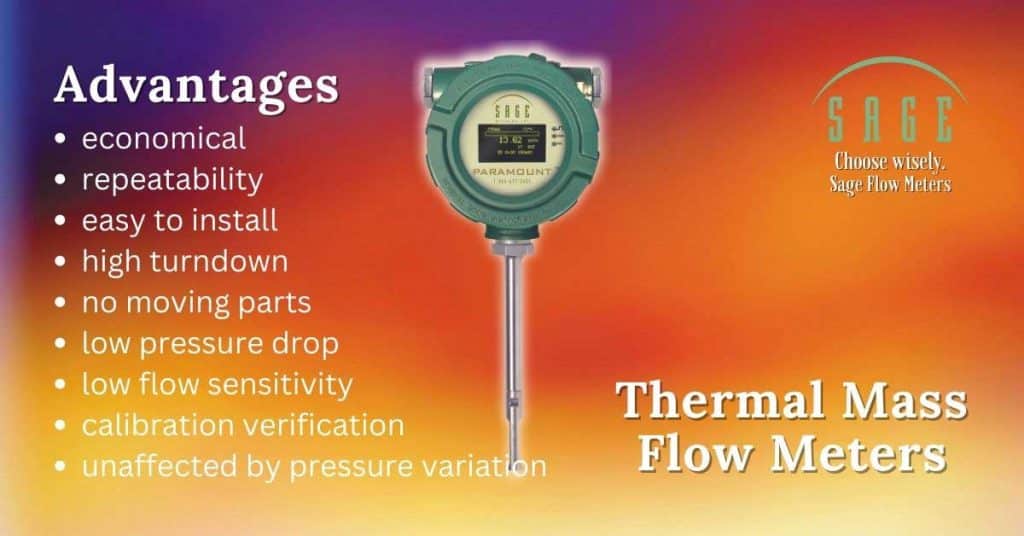

Sage Flowmeter Developments

Sage Metering introduced the first hybrid-digital thermal mass flow meter, providing a quantum leap in flow meter performance. Then Sage introduced the first easy-to-use on-site calibration verification method, which opened new markets for permitting the meter for greenhouse gas reporting per EPA regulations and quantifying carbon credits per U.S. carbon credit protocols. The calibration verification has also saved users time and money by not having to remove the meter and return it for annual calibrations.

10 Examples of Gases Measured

Thermal mass flow meters are used in a wide range of applications (in many industries) to measure or monitor gases such as:

- Aeration air (e.g., in wastewater plants)

- Biogas measurement (landfill gas, digester gas)

- Combustion air

- Compressed air

- Flare gas

- Carbon dioxide (for beverage production and chilling)

- Argon (in steel production)

- Natural gas (for burners and boiler feed control, submetering)

- Nitrogen and oxygen (production)

- Methane

Applications

Energy Management Systems

Measurement and submetering of natural gas and compressed air to assist the user with energy utilization and cost accounting within an industrial facility

Industrial Process Control

Measure combustion air flow to improve boiler and furnace efficiency, additionally measuring vent air flow and drying air flow

Environmental

Ecological applications include flare gas flow measurements in the oil and gas industry; additionally, the meters are ideal for the low flow of biogas and aeration flow and assist with regulatory compliance in reporting greenhouse gas emissions and carbon credit verification

Facility or Business Management Systems (BMS)

Monitoring natural gas lines in campus or university buildings to assess energy inefficiencies and institute conservation measures; submetering, cost allocation, and leak detection

How do thermal gas mass flowmeters work?

The thermal mass meter measures gas flow based on convective heat transfer.

The Sage flow meters are available in either inline flow bodies or insertion styles. In either case, the meter’s probe inserts into a pipe, stack, or duct gas stream. Toward the tip of the meter’s probe are two sensors: resistance temperature detectors (RTDs) or resistance thermometers that measure temperature. The RTDs consist of durable reference-grade platinum windings clad in a protective 316 SS or Hastelloy C sheath.

The Sage proprietary circuitry maintains a continuous overheat between the flow and reference detectors. One RTD is heated by an integrated circuit and functions as the flow sensor, while a second RTD acts as the reference sensor and determines the gas temperature. As gas flows by the heated RTD, drifting gas molecules transport heat away from it, and as a result, the sensor cools, and the energy escapes.

This constant temperature differential must be maintained, even if there are wide fluctuations in gas temperature. The Sage proprietary sensor drive circuit keeps the differential, whether or not the gas temperature changes or however quickly molecules cool off the flow sensor.

The electrical power required to sustain this overheat denotes the mass flow signal.

Are thermal flow meters for gas or liquid applications?

Thermal mass flow meters are used almost entirely for gas flow applications. As the name implies, the meters use heat to measure flow, and they introduce heat into a flowing stream and measure how much heat dissipates using one or more temperature sensors.

This method works best with measuring gas mass flow. Due to heat absorption considerations, getting a solid signal using thermal mass flow meters in liquids is challenging.

What are the two approaches to measuring heat dissipation?

While all thermal mass flowmeters use heat to make their flow measurements, there are two different methods for measuring how much heat dissipates.

Constant Temperature Differential Meters

One approach is called the constant temperature differential thermal gas mass flowmeter. Sage Metering uses this method which utilizes two temperature sensors: a heated sensor and another that measures the temperature of the gas. The mass flow rate is computed based on the amount of electrical power or energy expressed in milliwatts required to maintain a constant difference in temperature between the heated sensor and the passive temperature sensor.

Constant Current Differential Meters

Because of its slow response characteristics, a second less popular concept is a constant current thermal mass flow meter. Meters using this method also have a heated sensor and another sensor that senses the temperature of the flow stream. The power or energy delivered to the heated sensor is kept constant. The mass flow is measured as a function of the difference between the temperature of the heated sensor and the flow stream.

Both methods are based on the principle that higher velocity flows result in a more significant cooling effect as heat redirects from the heated detector.

Why is measuring mass flow important?

What are the advantages of a thermal mass flowmeter?

- Thermal flowmeters have no moving parts, reducing maintenance and permitting their use in demanding application areas, including saturated gas.

- Gas mass meters calculate mass flow rather than volumetric flow. They do not require temperature or pressure correction, so there is no additional expense for purchasing and installing other equipment.

- Thermal flowmeters provide excellent accuracy and repeatability over a wide range of flow rates.

- Thermal flow meters can measure flow in large pipes.