Thermal flow meters measure the mass flow rate of gas. Here is a list of the thermal mass flow meter applications within specific industries and the common gases they measure.

In the market for a mass flow meter?

Thermal Mass Flow Meter

Thermal mass flow meters are popular in industrial applications because of their design. They have no moving parts, require no temperature or pressure corrections, and retain excellent accuracy over a substantial range of flow rates. Additionally, whenever there is a limited straight run, common in many industrial applications, and a developed profile cannot be achieved, flow conditioning can solve the issue. Flow conditioning can create a known and repeatable velocity profile and enhance the flow meter’s accuracy.

Thermal mass flow meters are popular in industrial applications because of their design. They have no moving parts, require no temperature or pressure corrections, and retain excellent accuracy over a substantial range of flow rates. Additionally, whenever there is a limited straight run, common in many industrial applications, and a developed profile cannot be achieved, flow conditioning can solve the issue. Flow conditioning can create a known and repeatable velocity profile and enhance the flow meter’s accuracy.

Industry and Thermal Mass Flow Meter Application

Industrial Processing Plants – Pulp and Paper, Steel, Chemical, and Petrochemical Plants

Compressed air monitoring

Natural gas to boilers

Combustion air flow to boilers

Hydrogen monitoring

Gas additives/gas mixing

Valve and regulator leak testing

Secondary air inlet control and kilns

Air and nitrogen purge monitoring

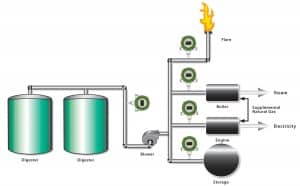

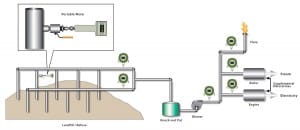

Digester gas/Biogas

Gas flow to test separators

Oxygen monitoring and water purification

Dryer air flow

Flare stack gas monitoring

Fluid bed dryer air flow

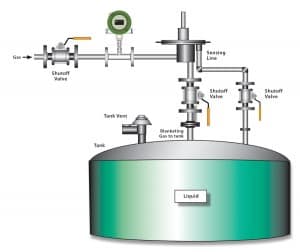

Nitrogen blanketing

Nitrogen seal leak detection

Propane line monitoring

Accumulator tank air flow

Steel/Aluminum Fabrication

Argon and nitrogen flow rates

Coke/oven gas

Air flow rates

Aluminum smelter chlorine and argon flow

Turbo airflow

Natural gas of annealing operations

Natural gas to smelting and casting ops

Nitrogen flows to the annealing process

Compressed air

Power Plants

Combustion air flow

Primary and secondary air flow

Natural gas to power generators/gensets

Heated air to coal mill

Condenser air leakage

Contaminant unit vent air flow

Water and Wastewater

Aeration air flow

Ozone measurement

Digester gas

Specialty Gas Producers

Nitrogen, argon, CO2, and hydrogen usage

Custody transfer/pay meter

Food Processing/Pharmaceutical Industry

Tablet and pill coating air and nitrogen flow

Exhaust gas

CO2 in beer manufacturing

Nitrogen in mayonnaise manufacturing

Ventilation systems

Compressor air flow

Hydrogen in hydrogenated oil production

CO2 fermenter off-gas

Automotive Industry

Compressed air monitoring

Natural gas consumption

Powder plant air flow

Paint booth/paint oven ventilation

Engine test stands air flow measurement

Fuel cell hydrogen flow

Mining

Compressed air to mine shafts

Ventilation air monitoring

Air injection into flocculation vessels

HVAC

Air balancing

Duct flow

Energy conservation

Cleanroom

Laminar flow benches

Glass/Ceramics Manufacturing

Oxygen and natural gas to burners

Natural gas to furnaces and kilns

Refining

Flare stack gas monitoring

Fuel gas monitoring

Air intake flow

Natural Gas Transmission

Natural gas to compressor stations

Natural gas to gas-fired compressors

Plastics Industry

Air and nitrogen flow monitoring

Environmental

Common Gases

- Air

- Ammonia

- Biogas

- Butane

- Chlorine

- Compressed air

- Carbon monoxide

- Carbon dioxide

- Digester gas

- Dump gas

- Ethane

- Ethylene

- Helium

- Hydrogen

- Methane

- Mixed gases

- Natural gas

- Nitrogen

- Oxygen

- Propane

If you have an application and need an accurate measurement of gas flow, contact Sage Metering and speak with one of our customer service representatives to recommend the appropriate meter.